Gravel Rascal Pro

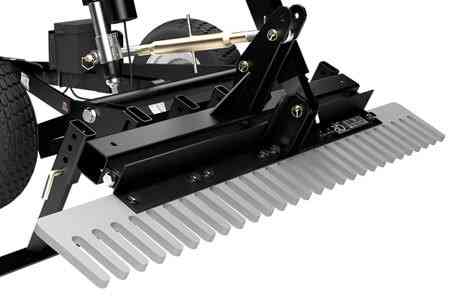

Ripping Teeth

The adjustable rippers give the Gravel Rascal the teeth it needs to break up most any hardpan surface. The ripping teeth are adjustable from 0 – 17.8cm to get to the bottom of the most demanding jobs, even potholes! They enable the Gravel Rascal to be used to maintain gravel driveways, parking lots, prep seedbeds, maintain trails, maintain food plots & so much more! The rigid design, and angle of penetration into the ground, delivers exceptional aggressiveness not match by any other Quad tool available. The tips are replaceable for reduced maintenance cost.

Profile Blades

ABI’s patent-pending Profile Blades are an innovative subsurface cutting component that temporarily replaces the ripping teeth and is used for 3 specialized purposes. First, it is used for conditioning the dirt (footing) of a horse riding arena. Second, it is used on baseball and softball infield surfaces. Third, it is used on driveways, after they have been significantly loosened, to remove remaining ridging and cut vegetation at the root level. The Profile Blades are only used for finesse dirt work.

Pivoting Rake - Pulverize, Grade, Rake, & Finish

By adjusting the rear manual jack, the Gravel Rascal’s, 1.27cm think hardened steel, rake can pivot up to 90° into a variety of finishing and grading positions. This adjustability enables the rake to pulverize clods of material, level and finish (with adjustability for varying material flow properties), spread loose material from a small pile, grade (by cutting already loosened material and dragging into low areas), and collect loosened surface rocks & other debris. The rake can additionally be adjusted completely out-of-play if unneeded for a particular job. This functionality enables the Gravel Rascal to beautifully finish gravel driveways and parking lots, collect and refill accessible washed-out gravel material, leave a perfect uncompressed seedbed, and even break-up aeration cores and manure in a pasture. While grading is possible without additional options, we HIGHLY recommend the optional electric actuator to control the wheel-lift system from the seat of the tow vehicle. This option greatly enhances the effectiveness and efficiency of the Gravel Rascal for “cut-&-fill” grading and spreading applications. The rake is replaceable in one foot sections to reduce maintenance costs.

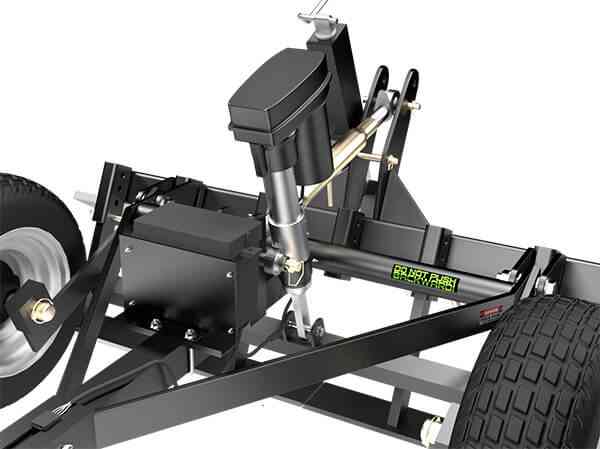

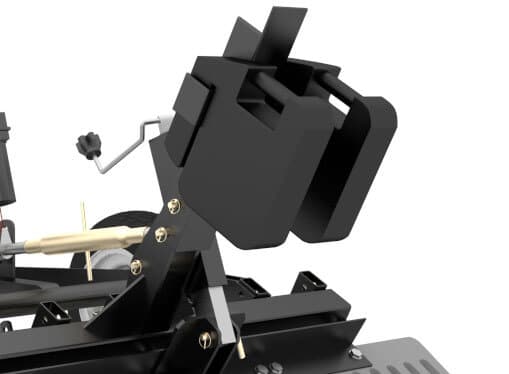

Patented Wheel-Lift System

With the Gravel Rascal’s patented wheel-lift system, the operator is in complete control! Without the wheel-lift system, pull behind implements are uncontrollable. The wheel-lift system is operated with a standard manual jack on top of the Gravel Rascal. Turning this jack raises and lowers the wheels, which in turn, raises and lowers the frame and ground contact points of the Gravel Rascal. This system may also be operated from the seat of the tow vehicle with the optional electric actuator (as shown). The wheel-lift system serve 3 purposes. First, it enables the tool to be lifted off the ground for easy transport all around the property. Second, it allows the operator to gauge or control the max depth of penetration into the surface. When the surface is extremely hard, the wheels may be raised “out-of-play” to allow the full weight of the tool to be placed on the ground contact components for more aggressive penetration. Third, when the wheels are all the way down, and the frame is lifted into the air, this allows for easy swapping out of underbelly components such as the ripper teeth and profile blades.

Large Stabilizing & Transport Wheels

The large 41.9cm tall x 20.3cm wide tires are a critical part of the patented “Wheel Lift System” and serve four important functions. First, they allow for quick and easy transport, over most any terrain, even at moderate speeds to get around the property quickly. Second, they stabilize the Gravel Rascal from pitching side-to-side ensuring consistency of grooming depth, the width of the unit, especially when maneuvering tight turns. Third, they enable the Gravel Rascal to “float” on loosened or wet material to minimize “sinking” into these soft material situations, which otherwise would alter grooming depth. This is a common problem for most competitive groomers. Forth, they gauge or control how deep the ground contact components go into the ground and hold a consistent grooming depth. When it come to tires, size matters. The taller and wider the tire is, the more stable a pull behind implement will be. These are high quality wheels with replaceable hubs, spindles, and bearings for long service life. These are not cheap caster wheels like are found on many competitive Quad tools.

Commercial-Quality Construction

At the core of the Gravel Rascal is a welded main frame built upon 7.6cm x 7.6cm tube steel. The frame is fully welded, except at pivoting joints, for rugged and long lasting service life. Every component of the Gravel Rascal is truly commercial grade built to take the abuse of hours of daily use. Commercial-quality construction and design excels when other tools fail. The Gravel Rascal is the toughest and most versatile Quad tool on the market.

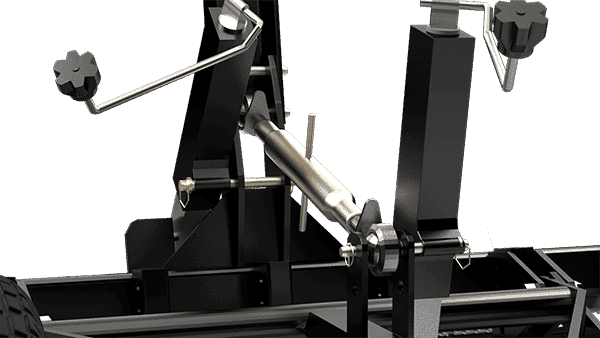

Ground Contact Pitch Adjustment

The turn-knuckle on the top of the Gravel Rascal is designed to enable adjustment over the angle in which the ground engaging components come in contact with the ground. This adjustment allows the operator to control the pitch of the ripping teeth and profile blade for a verity of applications and soil types. This feature is also a very handy, no tools required, way to adjust pitch for varying hitch heights of tow vehicles.

| Part # | RG4.5 | RG5.5 | RG6.5 | RG7.5 |

|---|---|---|---|---|

| Working Width | 1.37m | 1.68m | 1.98m | 2.29m |

| Unit Weight | 152kg | 164kg | 170kg | 175kg |

| Min. Horsepower | 18 hp | 22 hp | 25 hp | 30 hp |

| Min. CC | 400cc | 500cc | 600cc | 700cc |

| Hitch Type | Pin (Optional 2" Ball) | Pin (Optional 2" Ball) | Pin (Optional 2" Ball) | Pin (Optional 2" Ball) |

| 3-Point Hitch | Optional (For CAT 0 & I) | Optional (For CAT 0 & I) | Optional (For CAT 0 & I) | Optional (For CAT 0 & I) |

| Finish Color | Black Gloss | Black Gloss | Black Gloss | Black Gloss |

| Powder Coating | Yes | Yes | Yes | Yes |

Attributes

| Gravel Rascal Pro | |

|---|---|

| Connection | Ltd. CAT I 3-Point, Pin Hitch / Drawbar, Ball Hitch |

| Power Range | 18 – 23 h.p. Tractor, 23 – 38 h.p. Tractor, 400 – 600 cc ATV/UTV, 600 – 1,000+ cc ATV/UTV |

| Tow Vehicle | ATV, UTV, Sub-Compact Tractor |

PDFs

- Owner's Manual

- Actuator Set-up

- Attach Match Guarantee

- Food Plot Disc Manual

- 4.5' & 5.5' Mini-Box Blade

- 6.5' Mini-Box Blade

- 7.5' Mini-Box Blade

- Rascal Mini-Box End Kit

- 3-Point Assembly

- Driveway Guide

- Legacy Actuator

- Positions

- Set-up Guide

- Tips & Shanks Guide

- Warranty (Purchased Before 3/1/2021)

- Warranty (Purchased After 3/1/2021)

- Wheel Axle Replacement Instructions

Videos

Welcome Packages

Can’t find the resource you’re looking for? Let us help! Our support team can be reached at 877-788-7253

7 reviews for Gravel Rascal Pro

| 5 star | 100% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Joaquin Perez –

I was glad I made the decision of purchasing the Gravel Rascal because it has saved me many hours of smoothing out the rough ground on my landscaping project. I don’t think I’ll ever sell the Gravel Rascal when I am done. I know that I will use it again in the future. It is a valuable piece of equipment for anyone. Thank you for encouraging me to purchased it. It is so simple to use it. I really appreciated….and I have no regrets. I WILL RECOMMEND it to any of my freinds and family. I love it because it is MADE IN AMERICA and the quality that the manufacturer [ABI] has put into it is evident. It is so carefully designed with great precision of steel structure. Thank god is is not made in China. Many Thanks!!!!

Mike –

I used my new Rascal over Memorial weekend on my driveway. What an amazing machine! It worked 10 times as fast as a box blade and works 10 times better! You said it is a serious piece of equipment. You were right. This thing is a great design and is solidly built. I am surprised that a piece of equipment that is merely pulled behind an atv can dig in so well.

Don Lehmen –

The biggest thing for me when I was buying the Gravel Rascal was buying it over the phone, but now that I have it I couldn’t be happier with my tool. My salesmen Brad Ulick did a great job explaining how it worked and what it was built to do. The main reason I am so happy is because the tool does exactly what Brad said it would. I wasn’t finagled or tricked into anything and he made it very clear that it was my decision and wasn’t forcing anything on me. The Gravel Rascal is the best tool out on the market and I would trade it for any other drag.

Robert Carroll –

I have a gravel hill and when it rains the gravels washed off and with the rascal I can pull it right back up instead of going out and buying new gravel. The Gravel rascal does exactly what you guys said it would and works amazing.

Carolyn –

I bought the Rascal for my husband’s “big” birthday present and, even though it is a piece of work equipment, he was thrilled! Now we don’t have to pay other people to work the ground. We are saving money and that’s always a good thing. It’s probably already paid for itself. I am a very satisfied customer.

Ken Sierk –

I was looking for an implement to maintain the 1/2 mile entrance road into the plant I manage when I came across the Gravel Rascal. Since I’m months away form retirement, I’ve also been looking at business opportunities because I didn’t want to just sit around in retirement. I purchased the Gravel Rascal thinking at the very least, I would solve the pothole problem in our entrance road and maybe make a few dollars after I retired.

I was blown away at the quality and effectiveness of the Gravel Rascal. It did not look that formidable in the videos and I was a bit bit skeptical, but I was wrong. The next step up in products was exponentially more expensive and I’m not sure they would have produced any better results. First, ABI told the whole truth in their advertising. We have a very hard packed road due to the tractor trailer traffic on it and the rascal chewed this road up. We had been paying for a road grader prior to this and I can say with confidence that the Gravel Rascal produces an equivalent result, if not superior. Instead of having to sell driveway repair service, I have had people who have seen the results, ask me to recondition their driveways. I say recondition because normally we would keep adding rock to the plant drive but the Gravel Rascal brings the buried rock back to the surface producing an aggregate blend that packs much better than just rock addition and saves us money.

The icing on the cake is the quality of support from the company. ABI stands behind their product 100%. There are experts that answer questions, and they immediately correct any product issues. Well done ABI!

Tom –

I have a 1/2 mile gravel driveway. The Gravel Rascal works great to keep it maintained. It took a little practice to figure out the right cutting teeth depth and angle for the rake, but it is easy to pull with a UTV and is an invaluable tool to maintain our driveway. I didn’t get the electronic actuator, but I think that is an upgrade I’ll be making shortly.